作者: 时间:2021-12-20

本文主要翻译了美国Minusk隔振平台的使用手册,列举了减震平台的安装和调试注意事项,Minsuk的桌面型隔振台根据负载重量和尺寸的不同,分为BM-1,BM-4,BM-6,BM-8,BM-10,CT1,CT2,LC4,SM-1,MK26,MK52等12个系列。虽然减震平台的型号众多,但是他们的安装和调试注意事项几乎一致,请阅读以下减震平台使用说明。

Installation and Adjustment安装和调试,减震平台使用手册

BM-10 Bench Top Vibration Isolation PlatformBM-10桌面型隔振平台

|

尺寸: 12.2” W x 12.2” D x 4.6” H(310mm W x 310mm D x 117mm H) |

|

|

隔振台型号 |

隔振平台的载重范围(大约) |

|

10BM-10 |

0 - 10 lb (0 - 4.5 kg) |

|

25BM-10 |

10 - 30 lb (4.5 - 14 kg) |

|

50BM-10 |

30 - 55 lb (14 - 25 kg) |

|

75BM-10 |

50 - 80 lb (23 - 36 kg) |

|

100BM-10 |

75 - 110 lb (34 - 50 kg) |

BM-10 桌面型隔振平台使用手册

安装与调试说明

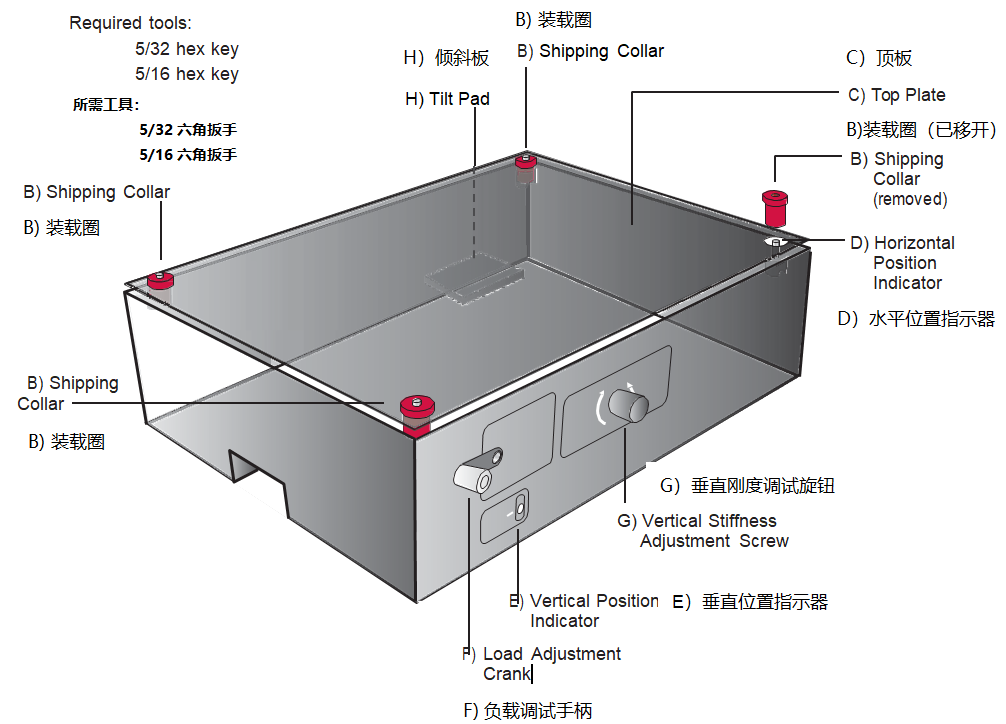

NOTE:DO NOT REMOVE SHIPPING COLLARS UNTIL INSTRUCTIONS INDICATE. SHIPPING COLLARS MUST BE USED WHEN MOVING ISOLATOR.

注意:在没有指示说明之前,请勿移动取下红色的装运载圈(B)。当移动隔振台时必须使用装载圈。

1. Make sure you have the correct model for your payload. Payload weight MUST be within the recommended range.

确保您的负载物重量和型号匹配正确,负载物重量必须在隔振台推荐范围内。

2. Place Isolation Platform on a solid, level surface.

将隔振平台放在坚固、水平的表面上。

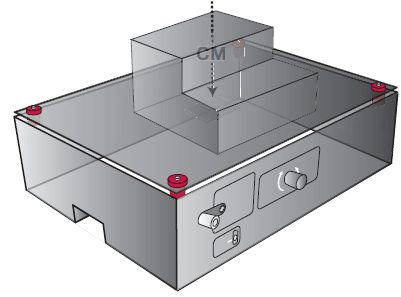

3. Carefully position payload on top plate so its center-of-mass (CM) is as close to center as possible

小心地将有效负载物放在减震平台顶板上,使其质心 (CM) 尽可能靠近隔振台的中心

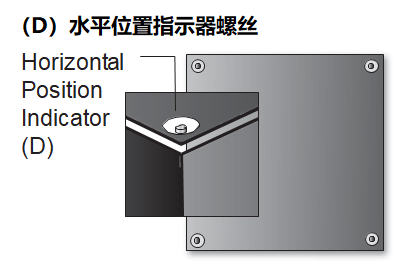

4. Remove the four (4) red shipping collars (B). STORE SHIPPING COLLARS IN A SAFE PLACE AS THEY MUST BE USED WHENEVER MOVING ISOLATOR. Replace the screws into the holes to serve as Horizontal Position Indicators.

卸下四 (4) 个红色(B)装载圈。将装载圈存放到一个安全的地方,因为在每次移动隔振台时都必须用到装载圈。 分别把螺丝重新装入孔洞中以用作水平位置指示器。

CAUTION: If payload covers shipping collar holes, collars must be removed before placing payload. Take extra care when placing payload without shipping collars attached. Do not replace screws as they may interfere with payload.

注意:如果负载物盖住了装载圈的孔洞,载圈必须在放置负载物之前取下。在没有卸下装载圈的时,放置负载物时要格外小心。 请勿更换螺钉,因为它们可能会影响到负载物。

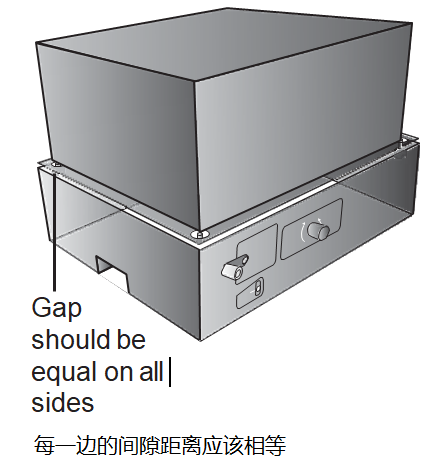

5. Check the gap between the top plate and the isolator cover making sure it is approximately equal on all sides.

检查顶板和隔振台盖板之间的间隙,确保其每一边的间隙距离大致相等。

6. Reposition the payload, as necessary,to level the top plate. It is recom- mended that you re-install the red shipping collars if you need to re-position the payload (see Step 3). However,it is not necessary if you take extra care repositioning the payload.

如果有必要重新移动负载物,使顶板的水平方向对准的话。温馨提示:您在移动负载物之前,最好重新装上红色装载圈(B)(见步骤3).当然,如果您在移动负载物时足够的小心,也可以不装红色装载圈。

NOTE: Cables, hoses, etc. connected to the payload can affect the horizontal and vertical position. If possible make the following adjustments without attaching the cables.

注意:电缆连接线,软管等等这些连接到负载物都会影响其水平和垂直位置,如果可以的话,请在不连接电缆的情况下进行以下调整

Floating Isolator Vertically(垂直方向浮动隔振平台)

The isolator comes from the factory adjusted to support the nominal weight, i.e., 25 lb for the 25BM-8, 50 lb for the 50BM-8, etc. Internal stops limit the vertical motion. The isolator must be “floated” between stops.

隔振台出厂前就经过调整以支持标称重量,例如型号25BM-8是25磅(规格书里是10 - 30 lb (4.5 - 14 kg)),50BM-8是50磅(规格书里25 - 55 lb (11 - 25 kg)。内部的阻塞限制了垂直方向的移动,该减震平台必须在阻塞之间“浮动”。

7. Check Vertical Position Indicator (E). The pin should be approximately centered on the horizon line. Turn Load Adjustment Crank (F) only clockwise when the pin is below the line,and only counterclockwise when it is above the line. If the payload weight varies from nominal weight by a few pounds/ kilograms it may take many turns (approximately 10 turns per payload pound, 22 per kilogram).

检查垂直位置指示器 (E)。 销钉应大致位于水平线上的中心位置。 当销钉低于水平线时顺时针转动负载调试曲柄 (F),相反,当销钉高于水平线时逆时针转动负载调试手柄(F)。 如果负载物的重量与标称重量不同时,比如相差几磅/公斤,这时需要转动很多圈(大概是每磅约 10 圈,每公斤 约22 圈)。

NOTE: To avoid damage never force the Load-Adjustment Crank. If pin cannot be easily centered on line, turn Vertical Stiffness Adjustment Screw slightly counterclockwise and readjust vertical position. Repeat as necessary. This is a very sensitive adjustment. Turn the screw only a few degrees each time.

注意:为了避免损坏,切勿强行大力摆动负载调节手柄。 如果销钉不能轻松地调试到中心位置,请稍微逆时针轻轻转动垂直刚度调试旋钮(G)并重新调试垂直位置。 有必要的话,反复调试操作几次。 这个调试按钮是非常敏感的。每次只能转几度螺丝,请勿用力过大。

Floating Isolator Horizontally(水平方向浮动隔振台)

8. Internal stops limit the horizontal motion. The isolator must be “floated” horizontally between the stops and it will be if the supporting surface is reasonably level. The Horizontal Position Indicator screws (D) should be approximately centered within holes.

内部阻塞限制水平方向移动。 通过调试水平螺丝(D),使隔振平台必须在阻塞之间水平“浮动”,如果支撑重量是合理的水平,就可以做到这一点。每个水平位置指示器螺丝 (D) 应大致居中,位于每个孔洞的中央。

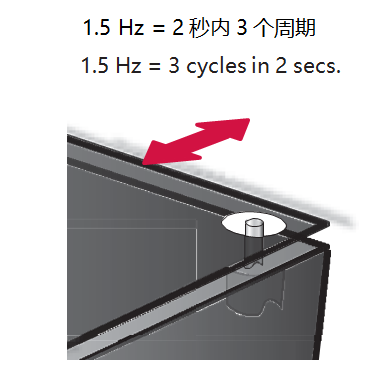

HORIZONTAL NATURAL FREQUENCY(水平固有频率)

9. The horizontal natural frequency can only be changed by varying the payload weight. Approximately 1.5 Hz is achieved when the payload weight is near the nominal (ie. 25 lb. for the 25BM-10). Increasing the weight lowers the frequency. Decreasing the weight raises the frequency. Ballast weights can be used to adjust the frequency.

仅当改变负载物的重量时,水平固有频率才会改变。当负载物重量接近标称值(即 25BM-10 为 25 磅)时,可达到大约1.5 Hz水平固有频率。 增加重量会降低固有频率。反之,减少重量,固有频率增大。压载物的重量可以用来精细调试频率。

Check the horizontal frequency by pushing horizontally on the edge of top plate to create small horizontal oscillations, then count cycles (one back and forth movement). For example 3 cycles in 2 seconds is 1.5 Hz. Depending on the damping, the isolator may only cycle 2 or 3 times.

通过水平推动顶板(C)的边缘,以产生小范围的水平振动来检查水平方向的频率,然后用来计算周期数(来回移动算一次)。例如,2秒3个周期,水平频率是1.5 Hz。该隔振台的周期可能只有 2 或 3 次,具体情况取决于阻尼。

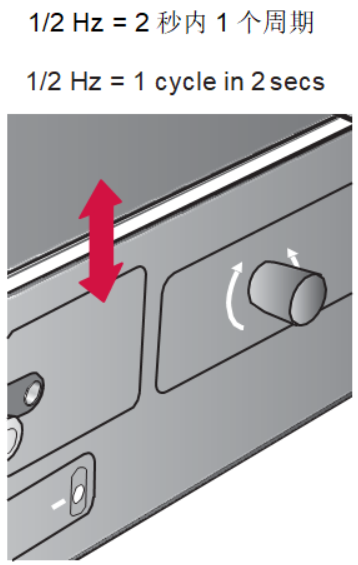

VERTICAL NATURAL FREQUENCY(垂直固有频率)

10. Check the vertical frequency by pushing down vertically on the top plate to create small vertical oscillations, then count cycles (one up and down motion). 1/2 Hz is equal to one cycle in 2 seconds.

通过垂直向下推压顶板(C)以产生小的垂直振动来检查垂直频率,然后计算周期(上下运动算一次)。 1/2 Hz 等于2 秒内一个周期。

The vertical natural frequency can be changed using the vertical stiffness adjustment screw (G), although this adjustment is seldom necessary.

This adjustment requires a 5/16 hex key. Turning the screw clockwise reduces the natural frequency, counterclockwise increases frequency. This is a sensitive adjustment. Turn only a few degrees each time then check the vertical position and frequency. Adjust further, if necessary.

使用垂直刚度调试旋钮(G) 可以改变减震平台的垂直固有频率,尽管这个调试旋钮很少需要用到。此调试旋钮(G)需要 5/16 六角扳手。 顺时针转动螺丝会降低固有频率,逆时针转动会增加频率。这个垂直刚度调试旋钮(G)是非常敏感的。 每次仅转几度然后检查垂直位置和频率。 如有必要,可再作进一步调试。

Note: Run any cables to the instrument with plenty of slack. Do not tie cables together as this will make them stiffer. Stiff and taut cables can stop the isolator from providing vibration isolation.

注意:将任何连接到仪器的电缆保持足够的松弛度。 不要将电缆捆绑在一起,因为这会使它们更紧绷。 僵硬和绷紧的电缆会阻碍隔振台的隔振效果。