Author: Time:2024-09-27

Resolution

targets, also known as optical resolution test targets or resolution test

targets, can be further subdivided into US Air Force 1951 resolution targets,

NBS 1963A resolution targets, etc. according to standards. The processing

techniques for crosshairs and resolution targets are basically the same, with

crosshairs inserted into the imaging surface of the optical system as the basis

for observation. This article introduces various standard resolution targets

that Highlight Optics can manufacture.

The target of

optical resolution testing is an important optical component used for

measurement calibration or resolution detection in optical systems. Commonly

used for fast and high-precision detection of optical parameters, such as lens

resolution and distortion. By using special techniques, graphic processing can

be performed on concave surfaces or graphic surfaces.

The application

of optical resolution testing targets is mainly to evaluate and test the

capabilities of imaging systems, and has been widely used in this evaluation

and testing. Resolution testing targets can be applied to the manufacturing and

production of complex optical systems in fields such as aviation, aerospace,

astronomy, as well as commonly used optical products in daily life. Resolution

test targets are suitable for evaluating the imaging quality of various optical

instruments and equipment, as well as for evaluating the imaging quality of

various lenses and optical components (such as projection objectives,

microscope objectives, camera lenses, CCTV lenses, etc.).

Highlight Optics

provides resolution modes for different standard resolution testing targets,

which are manufactured according to different standards such as USAF 1951, NBS

1963A, IEEE, ISO. Our company can produce positive targets (black pattern,

background reference color) and negative targets (black background, pattern

reference color). Highlight Optics also provide crosshairs widely used in

microscopes, sights, and monitoring lenses, which can be specially customized

and processed according to customer requirements.

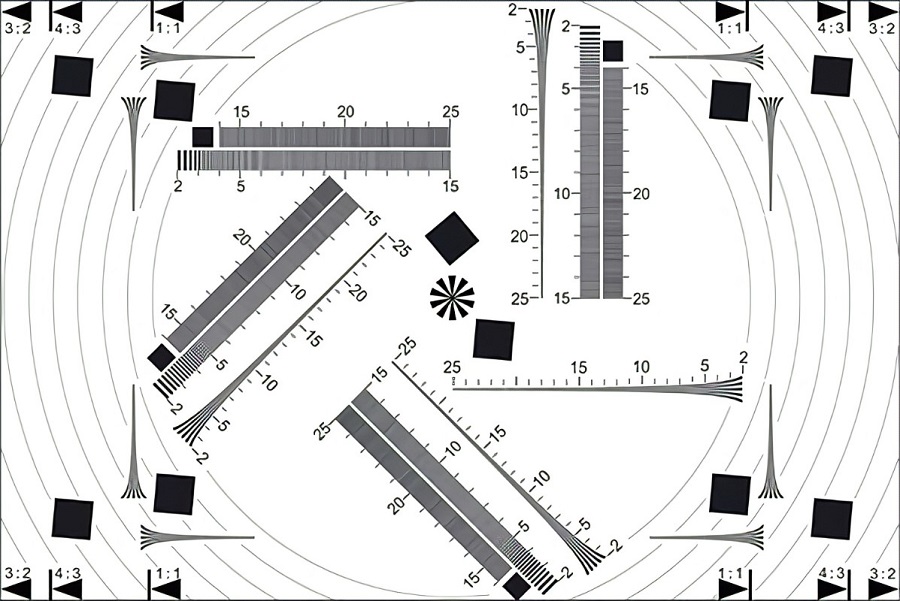

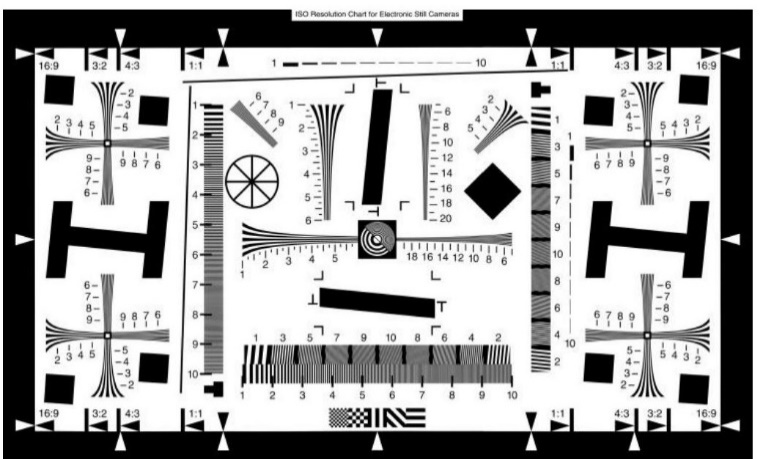

Resolution target sketch map

Optical resolution detection target is a tool used to evaluate the performance of optical systems or camera lens resolution. It combines different types of patterns, including Romchi Ruing parallel patterns, wedge-shaped wave patterns, and elements for detecting targets with optical resolution. There are two types of optical resolution detection targets: positive (dark pattern, bright background) and negative (dark background, bright pattern).

Positive targets are suitable for forward lighting and general applications, while negative targets are suitable for reverse lighting and high-intensity lighting applications. The resolution target of the US Air Force in 1951 was developed based on the US MIL-STD-150A standard and was created by the US Air Force in 1951. NBS 1963A is manufactured according to NBS 1010A standard, with a frequency range of 1-512 cycles per millimeter. Customers can choose different types of products according to their own needs.

Standard model for resolution target

|

Model |

Standard |

Dimensions |

Thickness |

Pattern Size |

Frequency |

|

RC-001 |

1951 USAF |

101.6×101.6 |

2mm |

50mm |

10-100 |

|

RC-002 |

NBS 1010A |

101.6×101.6 |

2mm |

25mm |

10-100 |

In addition to the existing resolution target standard models, our company can also provide various types of resolution targets, optical resolution detection targets, and markings based on the following standards.

Resolution test target

- Line Width: 12μm.

- Substrate: silica, glass, high borosilicate, etc.

- Diameter: Φ10mm-Φ50mm.

- Customizable.

The main purpose is to test the geometric resolution of short focus optical systems. The pattern is in the shape of a "meter". Widely used for image quality control of optical imaging equipment lenses.

Resolution test target

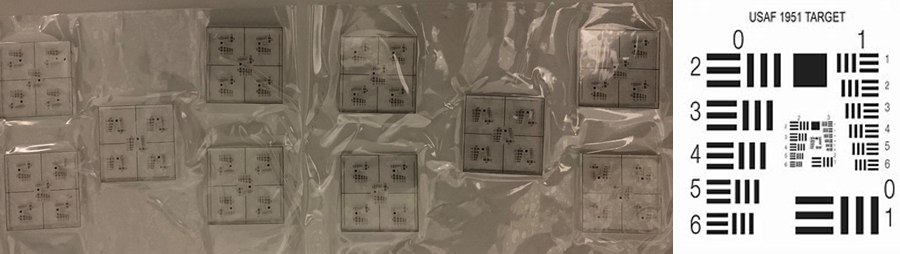

USAF 1951 Resolution Target

USAF 1951 resolution target are available in either positive (chrome pattern on clear background) or negative (clear pattern on a chrome background). The targets conform to MIL-S-150A.

|

Number of Line Pairs / mm in USAF Resolving Power Test Target 1951 |

||||||||||||

|

Element |

Group Number |

For High Res only |

||||||||||

|

-2 |

-1 |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

|

1 |

0.250 |

0.500 |

1.00 |

2.00 |

4.00 |

8.00 |

16.00 |

32.00 |

64.00 |

128.00 |

256.00 |

512.00 |

|

2 |

0.280 |

0.561 |

1.12 |

2.24 |

4.49 |

8.98 |

17.95 |

36.00 |

71.80 |

144.00 |

287.00 |

575.00 |

|

3 |

0.315 |

0.630 |

1.26 |

2.52 |

5.04 |

10.10 |

20.16 |

40.30 |

80.60 |

161.00 |

323.00 |

645.00 |

|

4 |

0.353 |

0.707 |

1.41 |

2.83 |

5.66 |

11.30 |

22.62 |

45.30 |

90.50 |

181.00 |

362.00 |

/ |

|

5 |

0.397 |

0.793 |

1.59 |

3.17 |

6.35 |

12.70 |

25.39 |

50.80 |

102.00 |

203.00 |

406.00 |

/ |

|

6 |

0.445 |

0.891 |

1.78 |

3.56 |

7.13 |

14.30 |

28.50 |

57.00 |

114.00 |

228.00 |

456.00 |

/ |

USAF 1951 resolution target

NBS 1963A

Resolution Targets

- Substrate:

soda-lime glass;

- Frequency:

1-18 lp/mm 50.8 mm;

- Diameter:

customizable.

- Complies With

NBS Standard 1010A.

NBS 1963A

Resolution Targets utilize the National Bureau of Standards 1963A Resolution

Pattern. The slides are ideal for precision optical testing. These slides have

a frequency range from 1-512 cycles/mm. NBS 1963A Resolution Target slides are

available in either positive (black pattern, clear field) or negative (clear

pattern, black field).

NBS 1963A resolution target

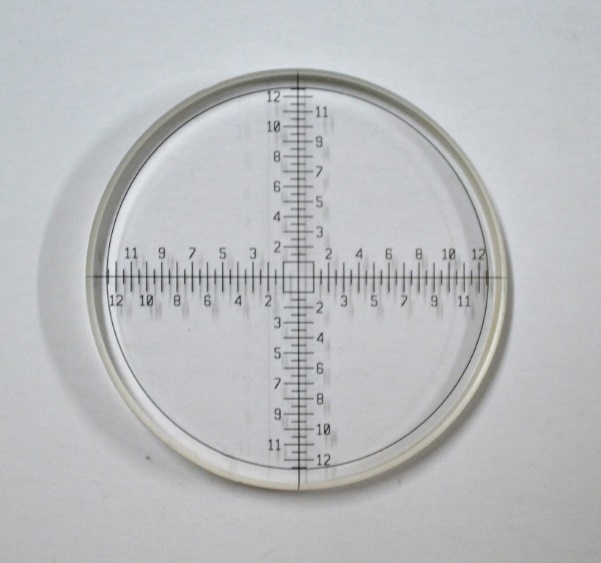

Reticles

Reticles is a glass flat plate with precise dividing lines etched on the surface, is inserted into the imaging surface or middle image surface of an optical device to serve as an observation reference. The accuracy of these reticles is extremely high, and even small flaws may affect the observation structure. Crosshair Lines can be composed of crosses, dots, circles, scales, and other combinations. Now it is mainly used in optical instruments that require measurement calibration, such as microscopes, telescopes, gun sights, and geodesy.

Curved reticle, also known as curved surface mirror with precise reticle or engraved patterns etched on the surface, aims to reduce the mass and volume of optical components, improve imaging effects, and is widely used in gun sights, optical measuring instruments, and other applications

|

model |

Substrate |

min line width |

Diameter |

|

flat |

silica, glass, high borosilicate, etc |

1μm |

Φ10mm-Φ50mm;customizable |

|

curved |

silica, glass, high borosilicate, etc |

20μm |

Φ10mm-Φ50mm;customizable |

Reticles

The resolution

targets and markings produced by our company are processed using

photolithography and LDW processes. If needed, please feel free to inquire

about customization.

Product Navigation : Microlens Array Off axis

link : Sina Blog Alibaba163 Blog

Copyright: Highlight Optics Co., Ltd. Address:4A150 No.1 Trading Plaza, China South City, Longgang District, Shenzhen, China

Phone: 0086 0755 89319011 Email: sales@highlightoptics.com